Fully-Oil Pad-Mounted Substation

Introduction to Fully-Oil Pad-Mounted Substations

Safe distribution substations with switches and fuses immersed in oil

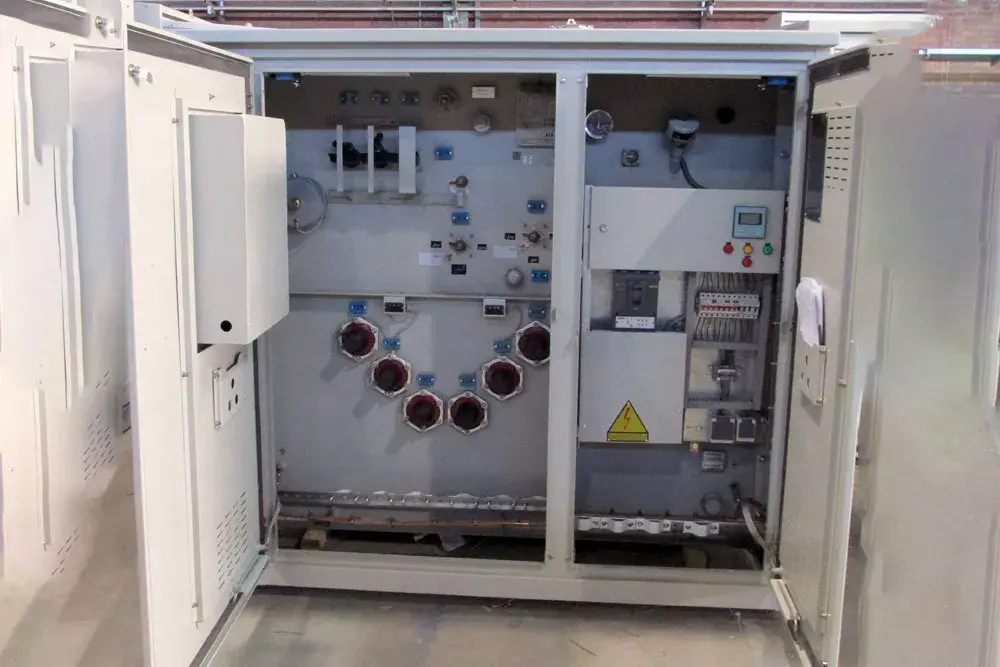

Fully-oil pad-mounted substations are prefabricated and integrated units where the cabin is mounted on the transformer wall, and their main components—including the transformer, switches, and fuses—are placed inside the oil chamber. These substations use a hermetic oil transformer with a neutral gas cushion and a radiator cooling system. Their design allows manufacturing only by transformer producers, making them a reliable choice for power distribution in industrial, urban, and specialized environments.

Features and Technical Specifications of Fully-Oil Pad-Mounted Substations

- Voltage Level: Up to 24kV

- Transformer Capacity: Up to 2500kVA

- Transformer Type: Hermetic oil transformer with neutral gas cushion

- Switches: Oil rotary load break switch

- Fuses: Bay-O-Net and current-limiting ELSP fuses

- Protective Equipment: Thermometer, pressure relief device, oil gauge, gas pressure gauge

- Protection Level: IP54

- Access: Two doors on one side for MV and LV sections, with safety lock and internal lighting microswitch

- Cost-Effective: Lower price compared to compact and semi-oil pad-mounted substations

Components of Fully-Oil Pad-Mounted Substations

- Hermetic Oil Transformer: With radiator cooling and gas cushion system

- Switches (Disconnectors): Two three-position oil disconnectors for MV section and one two-position oil disconnector for transformer feeder

- Fuses: Bay-O-Net and backup current-limiting ELSP fuses for reliable protection

- Bushings: 630A plug-in type resin bushings for MV, dedicated bushings for LV

- Capacitive Voltage Indicator: For incoming and outgoing feeders (no need for cable-mounted lights)

Applications of Fully-Oil Pad-Mounted Substations

- Urban and rural power distribution networks

- Industrial projects and factories

- Tropical regions with high ambient temperatures

Advantages of Fully-Oil Pad-Mounted Substations

- Specialized Design: Manufactured by the transformer producer according to modern standards

- Complete Safety: Locking system, voltage indicator, and microswitch for internal lighting

- High Durability: Three-layer industrial paint and corrosion/UV-resistant body

- Multi-Layer Protection: Combination of Bay-O-Net and ELSP current-limiting fuses for reliable protection

- Easy Installation & Maintenance: Compact design with one-side access to LV and MV sections

FAQ

- What is a fully-oil pad-mounted substation?

- It is a prefabricated substation where main components such as switches and fuses are immersed in oil and mounted on a concrete pad. It is suitable for industrial and urban environments.

- What is the difference between this substation and a semi-oil pad-mounted substation?

- Due to the use of oil rotary load Break switches, its dimensions and cost are lower compared to semi-oil pad-mounted substations.

- In what types of projects can these substations be used?

- They are used in urban and industrial projects with space constraints, as well as in areas with high temperature and humidity.

- How is the protection system of these substations designed?

- Full protection is provided through fast-acting fuses (Bay-O-Net), backup current-limiting fuses (ELSP), thermometer, pressure relief device, oil gauge, and gas pressure gauge.

- Is customization available?

- Yes, the substation can be designed according to required power, voltage, switchgear type, color, and environmental conditions.

- Do these substations require special maintenance?

- Yes, due to the hermetic design and internal protective equipment, they require minimal inspection and maintenance, resulting in a longer operational lifespan.